By Avigayil Kadesh

Oree Advanced Illumination Solutions, a revolutionary Israeli lighting company, coincidentally is based in a Ramat Gan office building called Beit Or (House of Light). Perhaps that augurs well for this ambitious company.

Oree’s core product is LightCell, a small, thin panel spread uniformly with LED (light-emitting diode), which directs light across its flat surface. This disruptive technology is light years beyond Thomas Edison’s light bulb.

“What’s unique is how thin it is, just four millimeters, and the unusually high lumens per watt,” says Chief Financial Officer Amir Steklov, showing a prototype installed in a conference room at Oree’s two-floor R&D headquarters.

The LightCell gives off more than 90 lumens of light per watt of energy, he explains. In practical terms, that means Oree’s five-watt solo module gives as much light as a 40-watt bulb.

A brighter alternative

Old-fashioned light bulbs are energy-inefficient, and while fluorescent bulbs are plentiful and cheap, the light quality is poor and they cannot be recycled. LED currently is the industry darling, and it is this technology that Oree has brought up a notch with the help of embedded chips and remote phosphor technology.

Oree, which means “my light” in Hebrew, is by no means the only player scrambling to find more energy-efficient, longer-lasting and lower-cost lighting alternatives.

International powerhouse Philips introduced a prototype 200 lumens-per-watt LED fluorescent tube in April 2013, potentially the world’s most efficient lamp. Companies such as Samsung are investing heavily in OLED, a thin one-layered organic LED product. And edge-lit LEDs provide backlighting for thinner televisions.

Steklov says Oree's LightCell offers the best of each, balancing several desired attributes in one product. The Philips tube takes up a lot of space; the OLED costs more and gives less light than the LightCell; and edge-lit LEDs cannot deliver the same uniformity of light.

“A lot of companies can bring the thinness or the uniformity, but we are the only company in the world that can bring it all together in one package,” says Steklov.

The idea originated when television producer and serial inventor Eran Fine was sitting in the dentist’s chair and thinking about how the large overhead light could be improved upon.

He teamed with engineer Noam Meir to establish Oree in 2006, backed by funding from Genesis Partners in Israel, Gimv in Belgium, FGC in Japan and Epistar in Taiwan. Neither founder is with the company any longer, but the product design is strongly protected with patents in the United States, Europe and China.

Peter van Strijp of the Netherlands, previously CEO of Philips Lighting, agreed to join Oree as CEO in 2012. “When we shifted from R&D to sales, we looked for a figure in the industry who can open doors,” Steklov explains.

“Oree envisions the future of lighting in which new form factors will be developed that unleash the full potential of LED technology,” said van Strijp. “Our expanded range of planar lighting modules will enable designers and fixture manufacturers to innovate and create new form factors that previously were unimaginable.”

Available in three basic sizes – solo, duo and quad – Oree’s futuristic module can replace incandescent or fluorescent bulbs, providing high-quality light while saving on cost and energy consumption.

The Israel-designed product is available in a large range of color temperatures, from cool white to warm white. It has an expected lifespan of 50,000 hours, it’s dimmable, and it can be controlled by computer.

On the market only since August 2012, LightCells are being made at a rate of 100,000 units per month in Thailand. Oree sales teams in Europe and Asia are selling them to a growing number of lamp manufacturers.

“We are starting to present our portfolio of products at exhibitions around the world,” says Steklov.

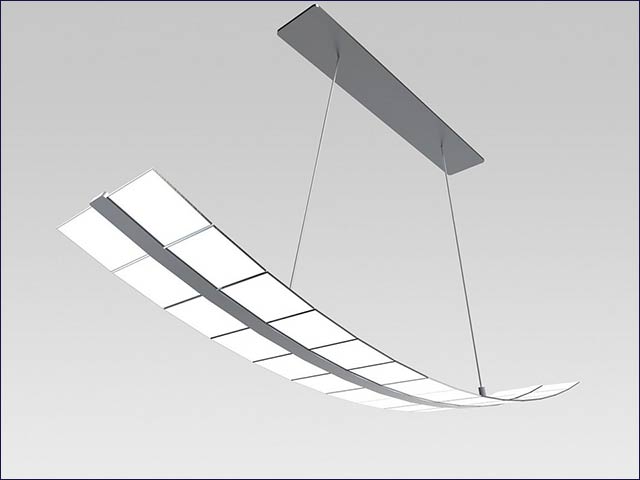

A suspended fixture fitted with LightCells

LightCells can be integrated into suspended fixtures, task lighting, decorative lighting and desk lamps, to name a few applications. Some customers are using them in emergency lighting and corridor orientation lights for hotels. A refrigerator manufacturer is interested in using the modules to light up the shelves, and IKEA is considering using the Israeli product to illuminate the undersides of cabinets.