By Sarah Carnvek

Even in winter, the AFIMALL shopping complex in Moscow has a beautiful, verdant green exterior. In Paris, the renewed façade of the French headquarters of Barclays depicts what look like folded pages of marble. And the Glass Farm in Holland never loses its nostalgic touch.

Thanks to an Israeli company's unique ceramic digital glass printing solution, architects around the world are giving the urban environment an arty facelift.

The Kfar Saba-based company,

Dip-Tech, has come up with a 360-degree printing solution that uses durable ceramic inks to digitally transfer any image onto panes of glass and in the process turn every building into a possible canvas.

"Many of the key luminary architects use our technology for their needs," says CEO Yariv Matzliach. He lists among them Frank Gehry, Parker Warburton Team Architecture, Rainer Oestereich-Rappaport and Sir Norman Foster.

They've made it easy, too. With just a click of the mouse, the image on one's computer screen can be transferred to Dip-Tech's specialized digital in-glass printer and printed using patented weather-resistant digital ceramic inks. The image can be used on both exterior and interior glass.

Outdoor art

Dip-Tech's solution has turned hospitals, shopping centers, museums, office buildings and universities around the world into works of art.

The roof of Norway’s National Museum of Rock and Pop Music is constructed of hundreds of glass panes digitally printed with the covers of Norwegian music albums. Backlit by more than 14,000 LED lights in many colors, the album colors constantly change and create an amazing effect.

The Harlem Hospital in New York is another beautiful example with its full-color building façade made of glass panels in the colors and styles of 1930s Harlem art and culture.

Scenes of a Russian forest, accomplished with digital

ceramic ink printing, adorn the AFIMALL in Moscow "Digital printing makes it possible to incorporate and express ideas that until now were left on paper," said architects Jesús Zafra and Javier Alarcón, who built a landmark office building in Spain.

Dip-Tech sells its solution – image processing software, ceramic inks and digital printers -- to glass processors and they fabricate the glass to the specifications of architects and designers. The glass can be used for super constructions, façades and many interior applications including backsplashes, shower doors, doors and walls.

Dip-Tech has the technology to print the widest scale of colors with its ceramic, all-weather and extreme condition inks. Unlike UV printing, the ceramic inks fuse into the glass, explains Matzliach. And that protects them from ever fading so the printed design will stay as long as the glass does.

Matzliach keeps tabs on the company's copycats. He says there is competition coming from Taiwan, Spain and Austria, but claims: "They are still a few years behind us. Technology evolves and we need to maintain our leading position. That's why we're investing in R&D to keep our edge."

"We have patented our technology with the Hebrew University of Jerusalem to develop patented ceramic inks. We have patented our printers as well. We have very strong intellectual property," he says.

Sustainable architecture

The buzzword in the world of architecture today is “sustainability.” And Dip-Tech's solution gives many meanings to the word.

Environmentally speaking, the actual glass being used in construction is always made of recycled products. Moreover, glass is known as one of the most sustainability-friendly materials available for architecture and interior design because it is non-toxic and transparent.

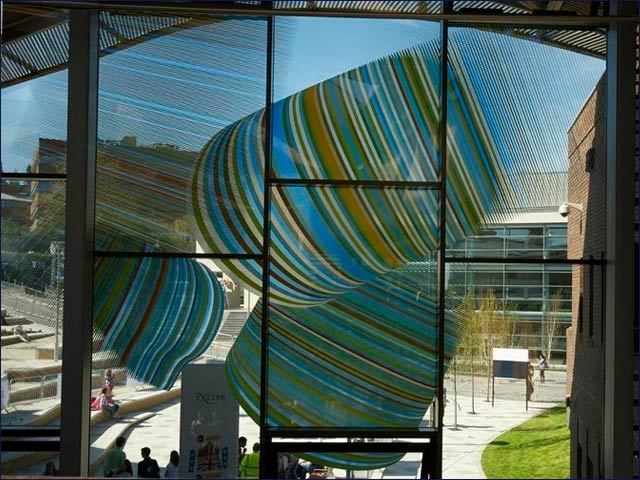

This award-winning design distinguishes the Forum

building at the University of Exeter, UK Matzliach says Dip-Tech's digital ceramic inks, when printed on glass, support multiple sustainability functions, including energy efficiency, solar/light control, light diffusion and transmission, glare reduction; urban renewal and building preservation; electrical conductivity; and use of low-impact materials.

He points to the Mansueto Library at the University of Chicago as a prime example. "The digital in-glass printing on the glass dome reduces energy needs as it blocks 73 percent of solar heat gain while admitting 50% of visible light," he says of the state-of-the-art project.

At the Sports Science Center of Murdoch University in Perth, Western Australia, architects built two enormous glass walls that let natural light into the gymnasium and exercise areas. On the exterior are colorful sports-themed murals that stand up to the country's strong UV rays and also protect the interior from UV radiation.

The Dip-Tech technology has two other standout sustainable applications: a slip-resistant ink and an anti-bird collision feature whereby the bird can see the glass from a distance.

The company started in 2005. Headquartered in Israel, it has sales offices in the US and Europe. Sales this year are expected to reach some $30 million. The company has shown a growth rate of 30-50 percent since 2010.

Holland’s Glass Farm "Every year we see more façades, buildings and hotels adapting our solution. My vision is that all printed glass will be printed with our technology because of its multicolor options and sustainability-supportive qualities. There's no better option than digital ceramic ink," asserts Matzliach.