By Sarah Carnvek

Go into almost any kitchen in Israel and chances are there's a quartz countertop. After all, this surfacing – which has become the fastest-growing countertop material in North America -- was created 25 years ago on a kibbutz on the shore of the Mediterranean Sea.

Caesarstone Sdot-Yam, or Caesarstone, was the first company in the world to use quartz to create a brand-new surface for kitchen countertops, vanity tops, tiles and sinks.

From a small kibbutz idea, Caesarstone has grown into one of Israel's biggest companies. Still headquartered at Kibbutz Sdot-Yam and produced in Israel (a fifth production line now being established), the brand is sold in 45 countries.

It is popular because it looks good, provides maximum resistance to staining and eliminates the need for sealing.

"Quartz is one of the strongest minerals on earth after diamonds, topaz and sapphires. In the combination that it appears in Caesarstone products – at least 90 percent quartz and some 10% binder products – the result is highly scratch-resistant, and something that doesn’t crack and doesn't stain," says Caesarstone CEO Yos Shiran.

Environmentally friendly

Quartz is also one of the most common minerals in the world. Caesarstone imports its raw material from Brazil, India or Turkey.

"It's like baking a cake," says Shiran of the process. "We take the crushed quartz, mix it with binders, press it at high pressures, send it to a curing process and then to polishing. The final product is a slab measuring 12 to 30 millimeters in thickness."

Caesarstone was the first company in the world to use engineered quartz. But the kibbutz, where it was conceived, never patented its product and today competitors abound.

However, Shiran sounds confident that the competition won't take Caesarstone's business away. “The original brand is important and it's about innovation and the actual product and not just copying the process. We also have the best service in the market," he says.

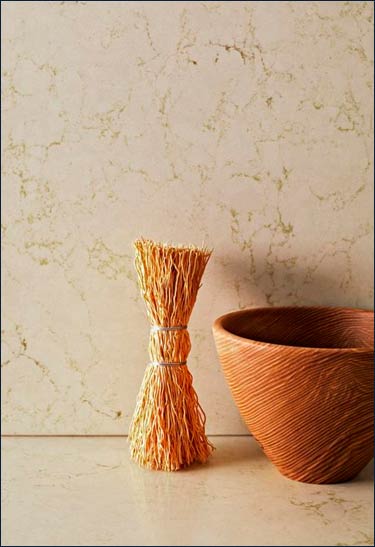

Like a chameleon, quartz surfacing can take on the look of natural stone, marble, granite or limestone. It's easier to take care of and is far stronger than these other materials, and it comes in smooth and sleek, textured and embossed styles. The company recently launched a new marble look.

Indistinguishable from marble Caesarstone is the first quartz manufacturing company to have received the ISO 14001 certification -- a standard recognizing competence in environmental management and performance.

In addition, the products meet the American Greenguard standards, and are accredited by the National Sanitation Foundation as safe for use in laboratories, healthcare facilities and food preparation environments.

There's also recycling going on. "Our recycled quartz stone surfaces contain up to 42% reclaimed quartz. We recycle 90% of the water used in making the product and we collect all the dust and gas emissions. We also try to preserve as much energy as possible," says Shiran. "It's very important to us to preserve all aspects of the environment."

From bankruptcy to IPO

Though Caesarstone is the leading company in the quartz arena today, says Shiran, the company almost didn’t make it.

In the mid-1980s, members of Kibbutz Sdot-Yam discovered that their cooperative was bankrupt because its terrazzo tile factory was producing a product that nobody wanted.

The CEO of the plant, Amos Amir, set out to find the next big thing in flooring material. During his travels through Europe, he came across an Italian company that produced stone surfaces using polyester to bind ground bits of stone. After production, the stone became dense and impermeable.

Upon his return to the kibbutz, he shared his ideas and experience with the members, urging them to switch over to using crushed quartz combined with polymer resins and pigments for a surfacing product.

"It really was a startup at the time. The idea to take quartz and work with it in this method was revolutionary," says Shiran.

But due to differences of opinion in how the concept was being developed, Amir left the kibbutz before the company properly took off.

Caesarstone in the bathroom The Caesarstone factory officially started operations in 1987 and struggled for the first few years. There are many arguments over who deserves credit for Caesarstone's ultimate success, but everyone agrees that Moshe Narkis, a Technion professor, was the one to strike the right formula for properly manufacturing quartz slabs.

In the early 1990s, the company settled its debts and signed international agreements with distributors in Italy, Holland, Germany and Australia.

In 2006, TENE Investment Funds injected $25 million into Caesarstone in exchange for a 21.7% stake in the company. Then in February 2012, Caesarstone filed with the US Securities and Exchange Commission to execute an initial public offering of up to $115 million and list its shares on the NASDAQ stock exchange. Caesarstone was named the second-best non-American IPO performance for 2012.

The company's revenues in the fourth quarter of 2012 increased by 13.6% to $76.2 million compared to $67.1 million in the same quarter of the prior year. “We believe we have the right global strategy in place to sustain our growth, build our operational capabilities, enhance our brand and drive value to consumers, customers and shareholders,” says Shiran.